ACCESSORIES

A silo is the obvious choice for the storage of bulk product in a storage or processing plant based on the capacity or performance of the plant.

A silo as such is not a section of a plant regardless whether it is for agricultural or industrial use. It is merely a component which must be equipped with various accessories in order to become a section of a plant and to allow for full functionality as well as safe operating.

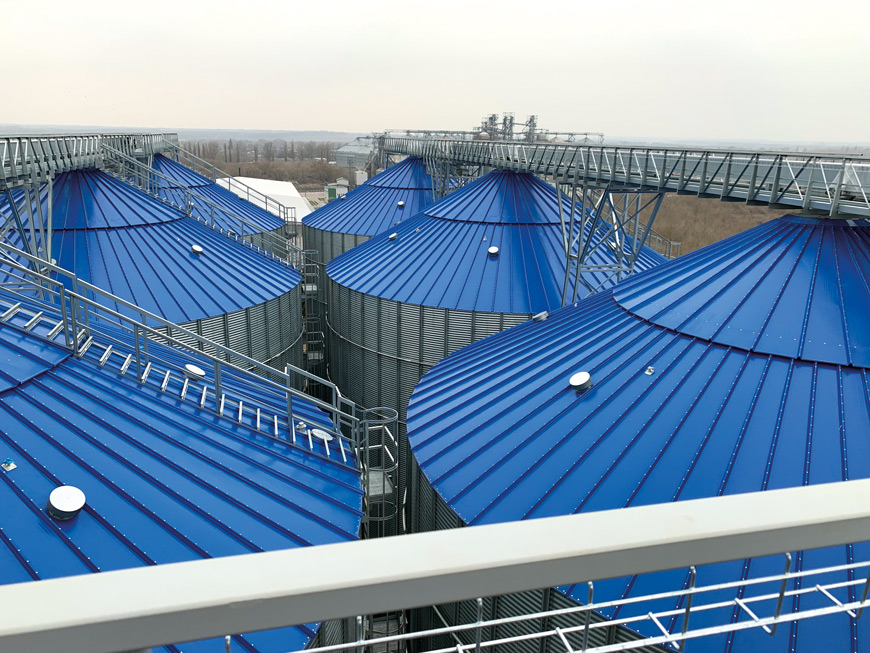

SIMEZA’s product range includes a wide list of accessories that can be selected according to the size, scope, and use of the plant. The accessories include those to allow for the proper design of the “basic” engineering elements such as ladders and stairs, platforms, and conveyor bridge, which is designed for the installation of conveyors - up to and including large size and heavy duty conveyors (all according to international work safety norms, and user-friendly comfort requirements) as well as those to allow for the proper control of the storage process, from level indicators or temperature control to elements for lateral gravity discharge and speed reducer.

The filling of silos occurs through the inlet of the central dome of the roof through gravity piping or with an overhead conveyor requiring safe access to the area. The inspection of the stored product is performed through the inspection hatch installed at roof eave also requiring safe access. Each silo storage plant must be unexceptionally equipped with stairs or ladders which allow for safe and quiet access to the overhead conveyor bridge or to the inspection platforms. SIMEZA manufacturing range of stairs and ladders includes:

- Stairs equipped with both side handrails and resting platforms, designed according to UNE EN ISO 14122-4:2004, manufactured with S-250GD hot dip galvanized warm rolled steel profiles and usually supported by an independent steel structure or by the elevator tower. Stairs are designed and installed in order to be the main access for the whole conveyor bridge system of the plant and to prevent individual access to the various elevated platforms of the plant.

- Ladders equipped with safety cages and resting platforms designed according to UNE EN ISO 14122-4:2004, manufactured with S-250GD Z600 galvanized steel sheet are usually anchored to the silo wall or the post of the conveyor bridge. Ladders are mainly installed for rare use and as emergency exits.

- Spiral stairs, directly supported by the silo wall allowing for quiet access to the individual silo eave but not to the overhead conveyor bridge.

SIMEZA’s manufacturing range includes several standard steel platforms either for inspection purposes or as rest platforms along the stairs/ladders to comply with safety regulations.

SIMEZA’s manufacturing range includes 2 types of conveyor bridges:

- Up to 600 t/h conveyors: The bridges are a modular and open framework type designed to support the dead weight of their structure and conveyor, the product weight, the live load of maintenance operators as well as snow and wind loads according to UNE EN ISO 14222. The bridges are manufactured as standard in several widths from 1200 up to 3000 mm and made of S-250GD Z600 galvanized steel sheet. They are equipped with handrails on both sides as well as grated floors and are supported by posts directly anchored to the reinforced vertical stiffeners of the silo wall.

- For heavy duty higher capacity conveying systems, the bridges are a modular and spatial framework type designed to support the dead weight of their structure and conveyor, the product weight, the live load of maintenance operators, as well as snow and wind loads according to UNE EN ISO 14222. The bridges are manufactured as standard in several widths from 1500 to 3000 mm and lengths from 12 to 36 m. They are made of S-250GD hot dip galvanized warm rolled profiles equipped with both side handrails and grated floors and are supported either by the reinforced vertical stiffeners of the silo wall or by an independent framework tower.

Both bridge types are equipped with widened platforms close to the drive and tail stations of the conveyor allowing for proper maintenance access.

The control of the upper level of the stored product allows for proper filling and in general for proper operation of the control system of the silo.

- Maximum level detectors are a standard accessory for all silos.

- Minimum level detectors are a standard accessory for Hopper Bottom Silos.

- Several types of detectors for maximum and minimum levels are available such as membrane, rotating paddle or capacitive type. They can be ATEX21 certified as optional.

- Detectors for continuous level measurement can be installed on request in order to monitor the level of the stored product at any time.

The first parameter which warns of fermentation or infestation of the stored product is its temperature. In order to prevent these problems silos can be equipped with a distributed temperature control system for the product which includes:

- A set of temperature probes hanging from the roof and homogeneously laid out and embedded in the stored product. The probes are equipped with temperature sensors that allow for monitoring of the temperature across the entire volume.

-

Software operating on an MS Windows base which is installed on the main plant control computer or on any other computer, PC, or tablet.

The software allows for:- A) Set up of alarm temperature for the entire monitoring system or for each individual sensor.

- B) Time programmable or continuous monitoring of the temperature of all individual sensors of all silos with memory and/or printing function.

- C) Warning of any temperature exceeding the setup to allow for quick reaction and avoidance of grain spoilage.

- D) Automatic switch-on of the forced ventilation, in case that the external air allows for grain aeration. It can be activated worldwide through smartphones or tablets.

- The installation of the temperature probes involves the installation of reinforced and additional roof beams.

- SIMEZA’s product range includes the supply of the above mentioned complete temperature control system, with ATEX 21 certified probes..

The stored products are mainly cereals, wheat, maize, paddy, oilseeds and other grain crops and these organic substances exchange oxygen with the air in the intra-grain spaces. This process is exothermic and generates heat and water in the product, both of which can create problems such as fermentation or clogging. The easiest method to remove the heat and evaporate the water is forced ventilation performed by external electrical fans blowing the outside air or refrigerated air into the stored product.

To this extent the floor of the silos must be equipped with one of following systems included in the manufacturing range of SIMEZA:

- MESH PATTERNED CHANNELS: Embedded in the concrete floor of flat bottom silos allowing for the homogeneous distribution of ventilating air. The channels are covered by perforated steel sheet panels designed to support the loads of the superimposed product and prevent the stored grains -even small round rapeseed- from entering. In order to prevent contamination by insects all panels can be easily removed and residual dust in the channels can be aspirated.

- PERFORATED FLOOR: Made of steel sheet panels supported by a set of steel columns covering the whole section of the silos, designed to support the loads of the superimposed product and prevent the stored grains -even the small round rape seed- from entering.

- Steel channels installed in the hopper of Hopper Bottom Silos with circumferential layout which allow for the homogeneous distribution of the ventilated air into the product without limiting gravity discharge.

In order to compensate the volume of incoming product the roof of the silo must be equipped with vents allowing for the expulsion of the existing air. The same is required in reverse when the silos are emptied. SIMEZA silos are standard equipped with circulation vents.

When the silo is equipped with an aeration system and forced ventilation, the number, the total section, and the layout of the vents must be designed to allow for the homogeneous exit of the forced air without creating counter pressure.

The SIMEZA aeration system includes the supply of additional roof air vents designed as above.

The air leaving the stored product as a consequence of the forced aeration is usually warm and humid and can allow for water condensation on the cooler lower surface of the roof. This water will run along the inclined roof surface and affect the upper product at the periphery of the silo. In order to prevent this problem, the SIMEZA product range includes electrical extraction fans. These are installed in the roof in order to create an accelerated air flow along the lower surface of the roof and inhibit condensation.

After studying the installation (required air flow, required pressure, type of grain, environmental conditions, volume, and dimensions), the necessary fan will be determined, which can be medium or high pressure.

Its function is to increase safety during roof maintenance tasks and to facilitate easy access to the center of the roof in the silo from a platform located at the eaves.

Designed to maximize the airtightness of the silo during fumigation processes. It optimally and necessarily complements the complete fumigation system in silos, designed for correct gas circulation inside the silo.

SIMEZA offers a system for insulating both the roof and the cylinder, designed and optimized to keep the grain stored inside at a constant temperature, especially for countries with particularly hot climates. There is an option for an air chamber between sheets or insulation using foam.

At SIMEZA, we offer the option to customize the color of silo roofs with your corporate color.

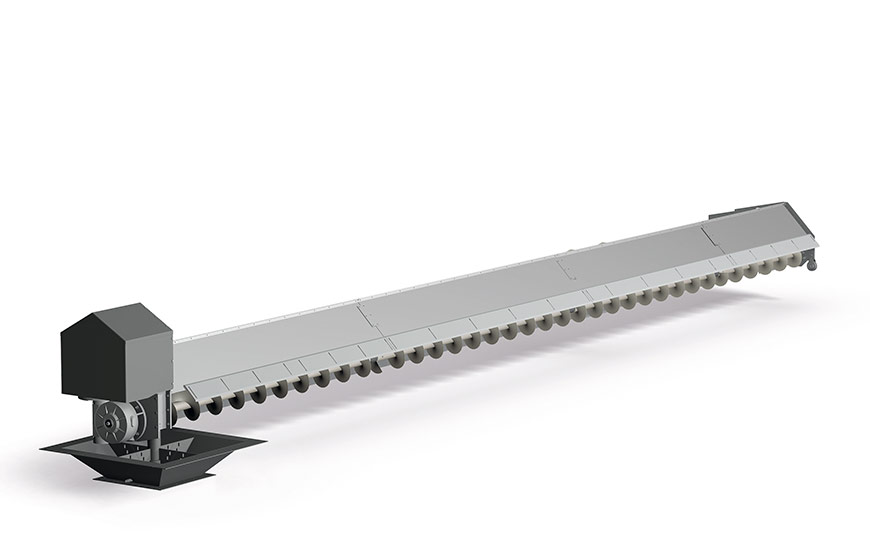

Flat Bottom Silos cannot be completely emptied by gravity as the stored products are granular (not liquid) and have an internal friction which does not allow for gravity discharge of the final cone. Sweep augers can be installed on the floor of the silos to convey the residual product to the central outlet. They are equipped with a central pivot and electrically operated drive unit as well as a peripheral mechanically operated drive which allow for simultaneous planetary rotation and radial conveying of the product.

The SIMEZA manufacturing range includes N°2 size of sweep auger, for 50 and 100 t/h capacity, both with ATEX 21 certification.

Silos can be equipped with a set of special buckets installed on the silo wall which allow for discharge of a significant portion of the stored product, by gravity, directly on to truck.

Seed cannot include broken grains as they reduce germination capacity. In order to prevent mechanical impact of the incoming grain against the bottom of the silo or the stored grain after a long drop, silos can be equipped with a grain fall speed reducer. It is installed along the wall of the silo and softly accompanies the grain during the movement to its final destination in the silo.