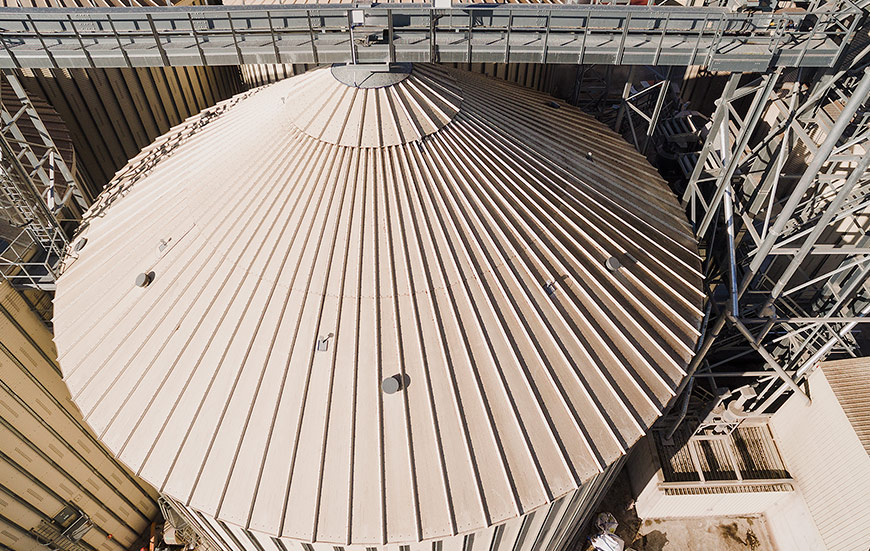

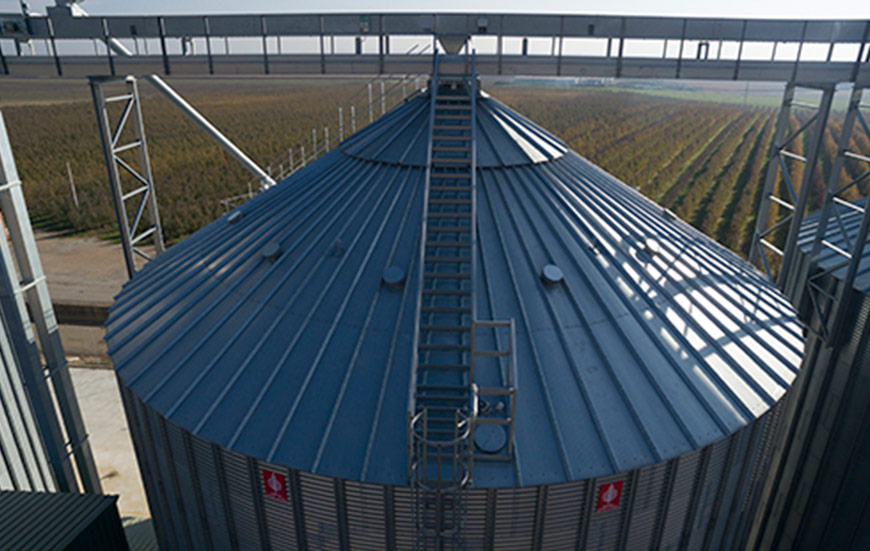

FLAT BOTTOM SILOS

SIMEZA corrugated steel sheet Flat Bottom Silos are designed for agricultural, industrial, commercial and strategic applications such as big farms, inland storage facilities, grain terminals, industrial plants fed with cereals such as flour mills, feed mills, rice mills, oil mills, and biofuel facilities. They can be used for both short -and long- term storage of cereals, maize, soya, paddy, oilseeds and any other granulated free flowing materials.

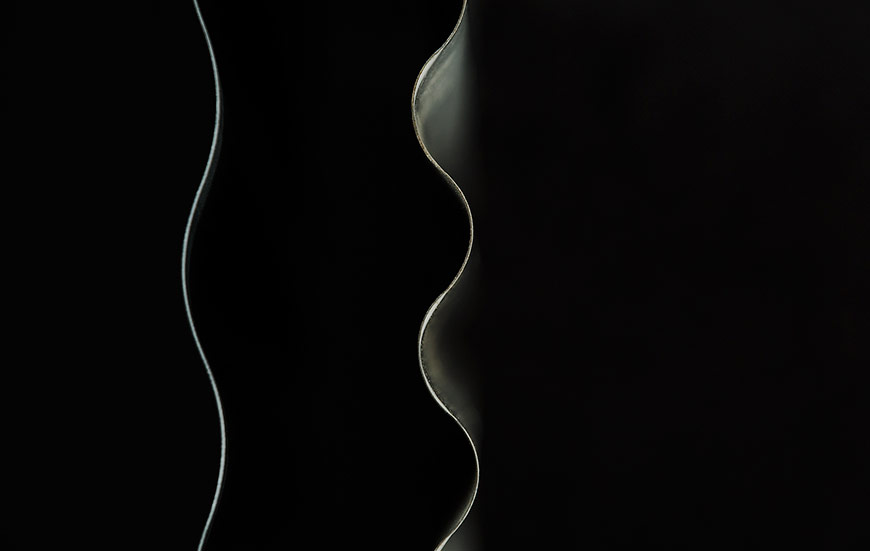

They can be designed according to either ASAE / ANSI American or Euro-Code European norms as per tender specifications or client choice and are manufactured in order to withstand the stress caused by continuous use, extreme temperatures, high winds, heavy snow and seismic loads. They also offer greater resistance to corrosion through thicker galvanization on the steel sheets.

SIMEZA offers a wide range of Flat Base Silos, from 4.6 to 32.10 metres in diameter and a storage capacity per silo from 40 to 25,000 m3 per silo.